Evolution of Design: 10,000 Milestones in Xanita’s Journey

In the world of design, milestones mark significant moments of growth, innovation, and transformation. For Xanita, the unexpected home of a leading design studio, crossing the threshold of 10,000 designs completed represents not just a numerical achievement, but a testament to a journey spanning over 15 years of constant creativity and evolution.

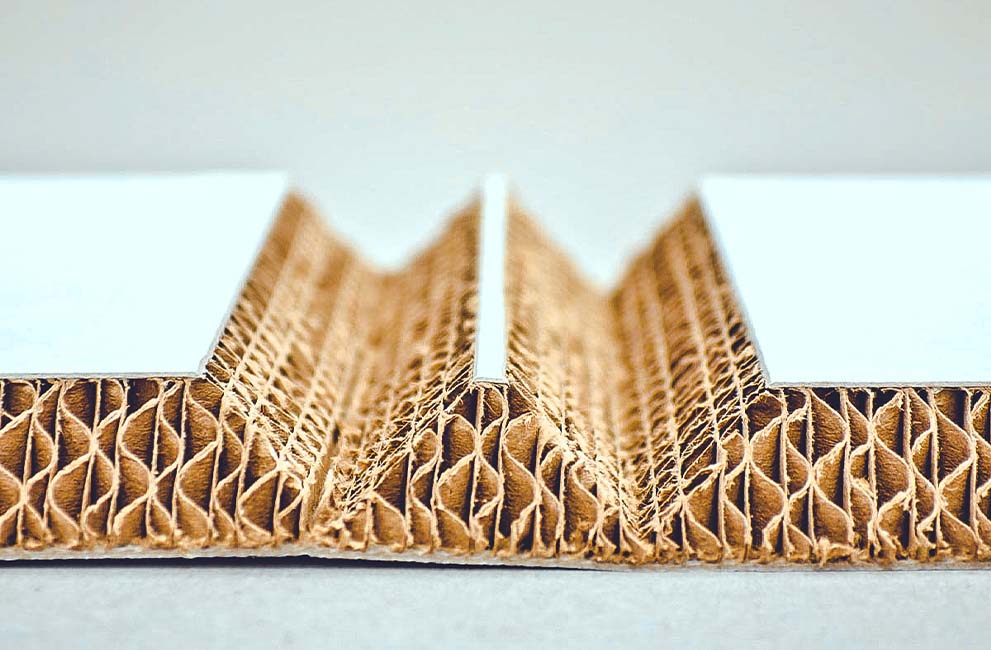

From basic friction fit designs that predated the v-cut tool to complex engineered projects, the trajectory of Xanita’s design journey reflects the remarkable advancement in design style and capability. What started as rudimentary concepts has now blossomed into intricate, awe-inspiring creations that push the boundaries of what was once thought possible with a paper board product.

But how did it all begin?

Xanita began as an idea around a kitchen table back in the early 2000’s. The idea of creating a new type of “eco” fiberboard started brewing, and this is where the development of Xanita board began. Two years of R&D and engineering later and in 2007 the first boards were run. Xanita was an outright manufacturing business back then which had developed a product at least a decade ahead of its time and this was a problem…

The consensus was that Xanita board was a fantastic product, but no one really knew what to do with it. The digital wide format printing industry as we know it today was itself in its infancy and was just finding its feet. Back then Zund was making printers and v-cutting wasn’t really a thing and printing was painfully slow with poor quality to boot.

After the first few years sales were slow and it became apparent that Xanita had to do something to survive. Either create a market for Xanita board and show the world what was possible with it, or disappear into oblivion as another failed startup, a product ahead of its time and gone too soon.

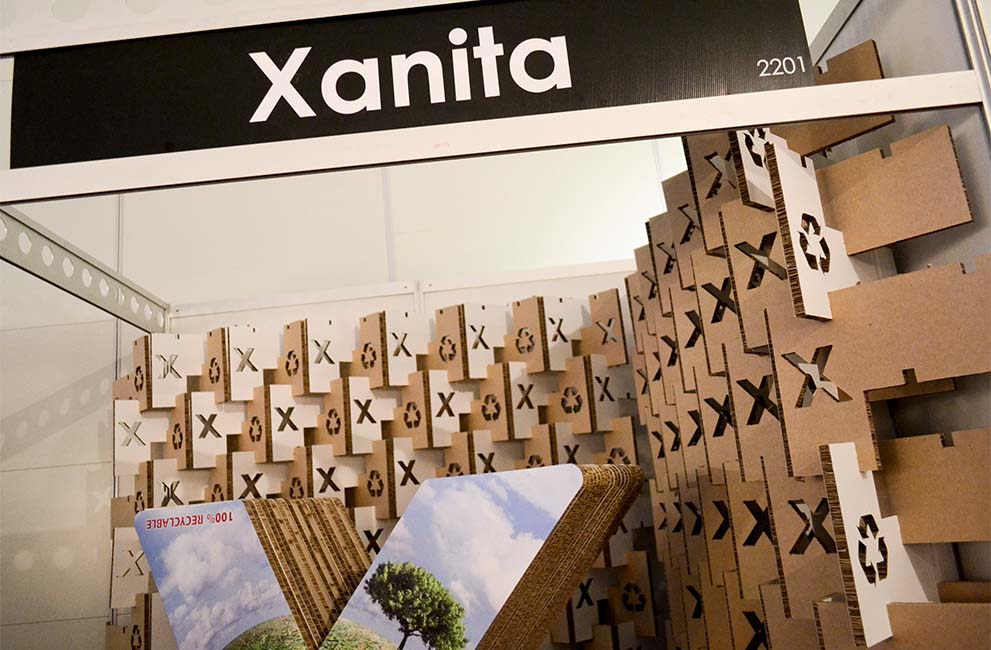

This fight for survival prompted Xanita to begin creating finished products, and by late 2010 Xanita converting was up and running. Attached to this new endeavour was a blooming design studio, with a complement more akin to a merry band of pirates than a world class design team. But they were creative, talented and eager to explore the new world they were about to create with Xanita board.

Early printing challenges.

The biggest challenge early on was figuring out how to get the board perfectly flat and the best method to print on the board. On flatbed printers, where the space between the printer and board is only 0.3mm, room for mistakes is minimal and the possibility of a costly head strikes a reality, so it was vitally important to get the surface as flat as possible to print on.

This is also where we discovered TSP (top sheet phenomena). In the early days, we found that most of our pallets, specifically the top sheet, started to bend, depending on humidity and other factors. Not only would this potentially cause damage to the printer, but it also influenced the quality of the design work at the time. Through R&D we discovered that by using a top sheet on all our pallets we could counter the effects of TSP on the sheets below.

Friction gets the fire started.

In the early days, Xanita’s designs may have been characterised by simplicity and interlocked friction fit pieces, yet they carried the seeds of innovation and ambition. As the studio honed its craft and embraced new technologies and techniques, each design became a stepping stone towards greater sophistication and complexity.

The journey from rudimentary designs to intricate engineering marvels is a testament to Xanita’s commitment to innovation and excellence. Through continuous experimentation and iteration, the studio has refined its processes, expanded its capabilities, and unlocked new possibilities in design.

The introduction of V-cutting with CNC cutters marked a pivotal moment in the evolution of design possibilities, particularly for Xanita board. This innovative technique revolutionised the capabilities of Xanita board, opening up a world of intricate and complex designs that were previously unattainable. By utilising V-cutting technology, Xanita’s designers gained the ability to create precise, sharp-edged folds and intricate patterns with accuracy. This breakthrough not only expanded the aesthetic potential of Xanita board but also enhanced its structural integrity, enabling the fabrication of three-dimensional structures and architectural installations with ease. In essence, V-cutting with CNC cutters transformed Xanita board from a versatile material into a cornerstone of cutting-edge design, allowing designers to push the boundaries of creativity and imagination like never before.

One of the most remarkable aspects of Xanita’s design evolution is its ability to leverage technology and prototyping to amplify creativity. Advanced software tools, such as Rhino, Sketchup and other 3D modelling software coupled with on demand rapid prototyping, have licensed designers to visualise and refine concepts with unprecedented detail and precision. It also helps that the digital wide format industry has progressed significantly over the past decade. This marriage of creativity and technology has enabled the Xanita design studio to tackle projects that would have been inconceivable a decade or two ago.

The growth of value added design.

As Xanita board started to reach the international markets more and more customers saw the potential of the product, however, most printers lacked the design knowledge and resources to fully exploit their use of the product. We realised that we had the ability to reduce barriers to entry and the hard lessons we had already learnt, by offering a helping hand. This is where the value added design service originated.

Xanita’s value-added design service has seen remarkable growth, emerging as a crucial resource for printers lacking 3D design capabilities. This service represents a strategic evolution for Xanita, as it extends beyond providing high-quality materials to offering comprehensive design support tailored to the specific needs of clients. By leveraging the expertise of Xanita’s seasoned designers, printers and brands can tap into a wealth of creative talent and technical know-how to bring their visions to life. Whether it’s crafting custom retail displays, exhibition booths, or promotional installations, Xanita’s design service ensures that every project is executed with precision, innovation, and flair. As a result, printers can confidently offer their clients a broader range of solutions, knowing that they have the backing of Xanita’s design expertise every step of the way. This growth underscores Xanita’s commitment to providing its partners with the tools and support they need to thrive in an ever-evolving marketplace.

With over a million V-cuts made, hundreds of thousands of sheets used and tens of thousands of renders completed, the 10,000th design milestone is not just a celebration of past achievements but a prelude of even greater things to come. As Xanita continues to push the boundaries of design, we remain committed to fostering creativity, embracing innovation, and creating awe-inspiring designs that captivate and inspire.

Be where the world is going.

Looking ahead, the future of design at Xanita promises to be even more exciting and transformative. With advancements in technology, materials, and design thinking, the design studio is poised to embark on new frontiers of creativity and innovation. Whether it’s reimagining spaces, revolutionising retail experiences, or shaping the future of sustainable design, Xanita is at the forefront of a design revolution that knows no bounds.

The journey from the first design to the 10,000th milestone is a testament to Xanita’s dedication to pushing the boundaries of creativity and innovation. As the studio continues to evolve and redefine what’s possible in design, one thing is certain: the best is yet to come.